Pioneering precision in Swedish skyscrapers

The revolutionary use of active GNSS control points and cutting-edge geomatics equipment is setting new standards for accuracy in the construction of high-rise architecture, as demonstrated by this skyscraper project in Sweden.

Towering at 246m, the Karlatornet will be Sweden's tallest skyscraper and is poised to redefine the skyline of the city of Gothenburg. Due to its impressive height, the construction work poses challenges of stability and precision. One key solution is the core wall control survey method, a pioneering technique ensuring the vertical alignment of high-rise buildings. With the revolutionary use of active GNSS control points, including the cutting-edge SinoGNSS T300 receiver, accuracy is being prioritized in this iconic structure, both during and after construction. This approach is setting new standards in the dynamic landscape of high-rise architecture.

The new 74-storey Karlatornet skyscraper holds symbolic importance in modern Swedish architecture and urban development. When completed, it will occupy an extensive footprint of 143,000m2 and soar to an impressive height of 246m, creating a historic milestone as Gothenburg's inaugural skyscraper.

Visualization of the Karlatornet skyscraper, seamlessly integrated into its surroundings. (Image courtesy: Serneke Group)

Its towering height presents construction challenges including stability, accuracy and safety. Tall buildings are susceptible to bending and swaying due to wind and loads, demanding precise alignment. Deviations from settling, shrinkage or tolerances pose structural risks. Even minor shifts can have significant consequences, underscoring the critical role of precision.

Elevating skyscrapers with the CWCS technique

The core wall control survey (CWCS) method represents an advanced technique designed to ensure the vertical alignment of high-rise buildings, particularly tailored for skyscraper construction ventures. Originally used during the construction of the Burj Khalifa in Dubai and subsequently applied in the construction of many high-rise buildings worldwide, this innovative system has now found successful application in the Karlatornet project at the request of the Swedish surveying company Teodoliten. Core walls emerge as pivotal components in the structural support of high-rise edifices and necessitate a layered construction approach, with each core wall element requiring multiple concrete pours.

The mastery of CWCS lies in its ability to meticulously align the self-climbing formworks and therefore the core walls with the vertical axis of the building as they are gradually constructed. This precision is the bedrock of ensuring stability and accurate positioning. The CWCS method harmonizes a suite of sophisticated tools such as GNSS technology, total stations, inclinometers and more to deliver pinpoint precision and rigorous control during the construction of high-rise buildings. This, in turn, safeguards the structural integrity and safety of the building, particularly when addressing deformations caused by external factors such as wind loading, sunlight exposure and seismic activity.

A total station operator sighting the four active GNSS control points to determine the coordinates of the instrument and the orientation of the primary axis.

What are active GNSS control points?

In the realm of high-rise construction, the continuous measurement of the positions of various elements at the summit of the building is a paramount requirement to ensure rigorous vertical alignment. Active GNSS control points, an ingenious technology leveraging GNSS, actively governs the building's positioning. Conventionally, four GNSS receivers each with a 360° prism screwed at the bottom are strategically placed atop the building to supply three-dimensional coordinate data for setting up the total station.

Furthermore, a reference station is established nearby to record its observations for use in post-processing calculations, thereby guaranteeing final high-precision coordinates for the 360° prism co-located with each GNSS receiver. The total station operator can sight the four active GNSS control points and determine the coordinates of the instrument and the orientation of the primary axis.

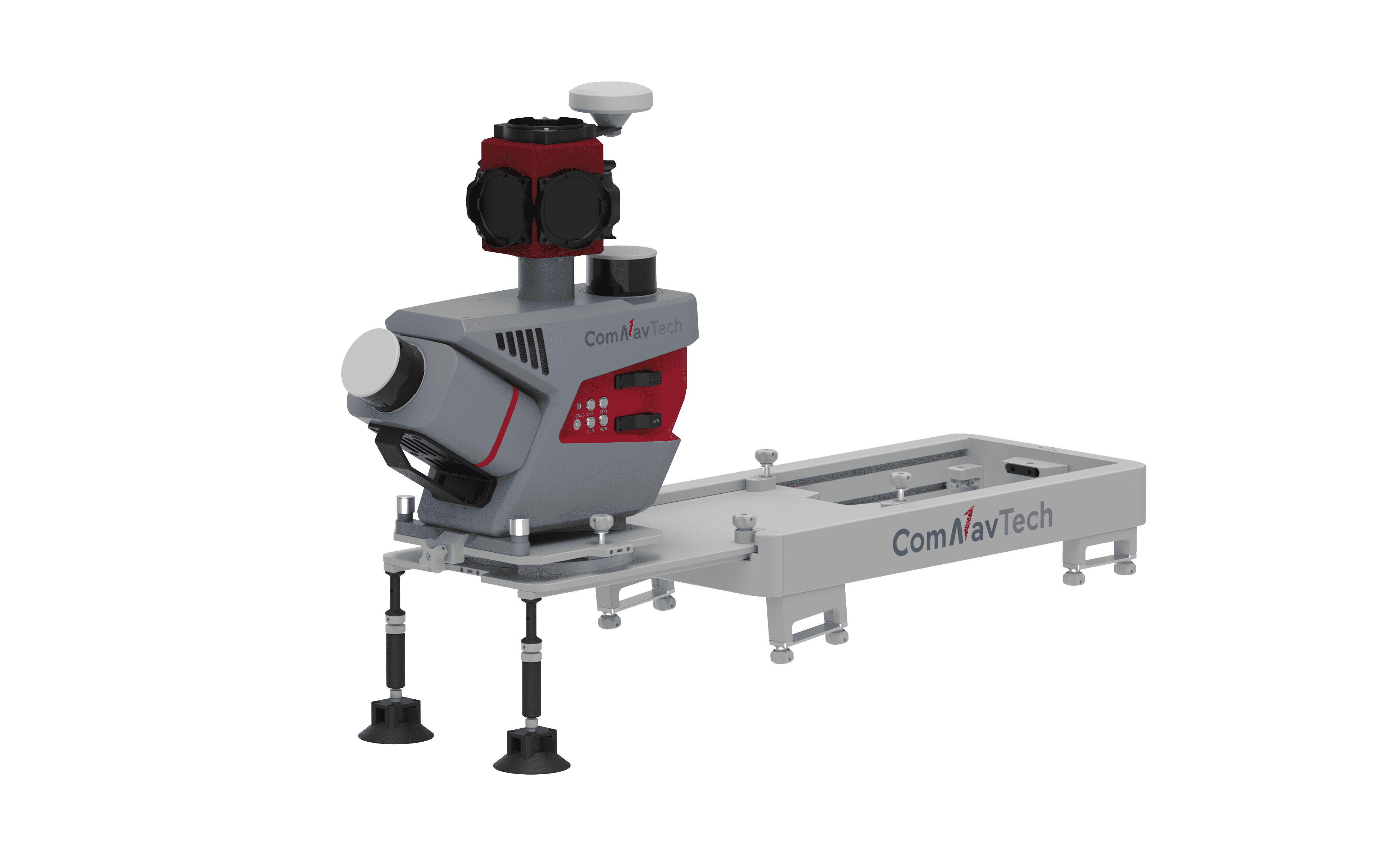

Typical setup of an active GNSS control point using the SinoGNSS T300..

The advantages

Throughout the construction process of the Karlatornet, four SinoGNSS T300 units serve as active GNSS control points, strategically positioned on the top platform of the building and providing comprehensive 3D coordinate data for the total station. A fifth unit is designated as the base station. Active GNSS control points boast a distinctive advantage as they offer an effective positioning method at high-rise construction sites without the necessity for an extensive array of ground control points that are often not visible from the top. This revolutionary technology empowers surveyors with amplified flexibility in their operations, all the while ensuring the vertical stability and accuracy of the building, ultimately mitigating measurement errors. Another advantage compared with the use of vertical laser plummets is that it is not necessary to have holes in the slabs and to keep those openings free from obstructions.

Furthermore, the adoption of the post-processed kinematic (PPK) mode represents a pivotal leap towards achieving unprecedented precision across various domains. PPK harnesses state-of-the-art technology and algorithms to augment positioning accuracy and refine data collection. By processing and analysing GNSS data subsequent to its acquisition, PPK mode diligently filters errors, yielding highly reliable and very accurate results. The coordinate accuracy obtained is within a few millimetres.

Procedure for setting up the four active GNSS control points.

Since the platform on top of any high-rise building moves under the various loads applied on the structure, the coordinates provided by the active GNSS control points must be corrected by the deflection of the building main axis. That is the reason to use the dual-axis inclinometers that are sequentially placed along the core walls. These high-precision devices output the tilt value of any displacement in X and Y in the building reference coordinate system. By using a rigorous least squares adjustment and knowing the floor height where these devices are placed, it is possible to derive the corrections in dX and dY that must be applied to the active GNSS control points to fit with the design coordinates where the self-climbing formworks are positioned.

Post-construction deformation monitoring

GNSS-RTK technology can also be harnessed for the post-construction deformation monitoring of high-rise structures. This crucial monitoring endeavour is designed to assess and document any potential deformations or alterations in shape that may manifest after the construction phase. Such deformations may stem from various factors, including (but not limited to) wind loading, exposure to sunlight, fluctuations in temperature, settling of the foundation and seismic activity. Monitoring these deformations stands as a linchpin for ensuring the structural integrity and safety of the building.

Typical results obtained by four sessions using active GNSS control points.

This assumes even greater significance in the context of high-rise structures that are inherently more susceptible to external influences. The SinoGNSS T300 receiver could play an instrumental part in deformation monitoring in the Karlatornet once construction work has been completed, thanks to its advanced RF and baseband chips, complemented by a unique Quantum-RTK algorithm. The receiver also delivers comprehensive support for multiple satellite constellation systems, effectively surmounting the constraints of traditional RTK methodologies in terms of continuity, accuracy, efficiency, availability and reliability.

Active GNSS control points with the SinoGNSS T300.

The future of high-rise buildings

As the Karlatornet project hurtles towards completion, it stands as an unequivocal testament to the inherent potential of modern construction methods and technologies. This significant project underscores the groundbreaking capabilities of GNSS technology in the realm of high-rise construction. As GNSS technology continues on its evolutionary journey in tandem with innovative measurement methodologies, it paves the way for an array of forthcoming milestones and pioneering advancements in the realm of high-rise construction projects. These towering marvels will persist in shaping city skylines as evidence of the relentless progression of modern architectural and engineering technologies, in which surveyors are playing a key role.

Cezary Modzelewski, a surveying engineer and temporary worker of the Teodoliten team.

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNavTech®

ComNavTech® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNavTech®

ComNavTech® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.